Need any help or advice?Contact Us

Downloads (3)

| Safety Datasheet (SDS) - EN | ||

| Technical Datasheet (TDS) | ||

| XT135 Processing Guide |

Specification

Fabric Specification

| Fibre Specifics | Toray T300 3k | |

|---|---|---|

| Colour | Black | |

| Type | Tooling Prepreg | |

| Resin Matrix | Epoxy | |

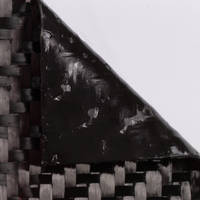

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric | |

| Filament Count | 3k | |

| Fibre Type | Carbon Fibre | |

| Brand | XPREG |

Weight and Dimensions

| Width | 1250 | mm |

|---|---|---|

| Consolidated Thickness | 0.7 | mm |

| Areal Weight | 250 | g/m² |

| Resin Weight | 67 | % |

Fibre Properties

| Min Cure Temp | 65 | °C |

|---|---|---|

| Max Cure Temp | 130 | °C |

| Max Service Temp | 135 | °C |

| Out-life (at 20°C) | 21 | Days |

| Freezer-life (at -18°C) | 12 | Months |

General Properties

| Gross Weight | 0.73 | kg |

|---|---|---|

| Brand | XPREG |

Shipping Information

WARNING!! HIGHLY PERISHABLE

This particular prepreg product is is highly perishable and for best results has a very short 'out-life' of just 2-3 days at room temperature. For this reason, we do not recommend ordering from the USA unless you are confident that there won't be any delivery delays and are aware of, and willing to accept the risks of international shipping of a highly temperature sensitive material.

Do NOT order this material during periods of high ambient temperatures (i.e. hot summer months).

Unless you plan to use the product immediately, it should be placed into frozen storage immeditely on receipt.

Because of their perishable nature, we only ship prepregs internationally on priority (air) services. As a result of this, it may not always be possible to order prepregs at the same time as some large or bulky items. If this is the case, the shipping calculator will warn you and suggest that you remove large items or place separate orders.

Customs Clearance

Although orders to the USA are delivered 'duty paid', orders over $800 are still subject to a 'formal' customs entry procedure where US customs may contact you to confirm some details. We remind customers that customs clearance is your responsibility and that when ordering perishable 'prepregs' it is important to respond quickly to any such request in order to avoid delay and potential damage to the material. Easy Composites cannot be held responsible for damage caused to prepregs during transport as a result of customs delays. By placing an order for prepreg materials, you accept these conditions of sale.

Package Size

When packaged, this product is over 1m in length. A small 'additional handling' charge will be included in the shipping cost.

Delivery Cost

To find the cost for delivery of this item to your address, add it to your cart then use the instant shipping calculator on the cart page.

XT135/S 250g (7.2oz) 3k Tooling Prepreg Carbon 1250mm (49")

- XPREG

- XT135S-C311T2-250(1250)-1

- 5/5 Average rating

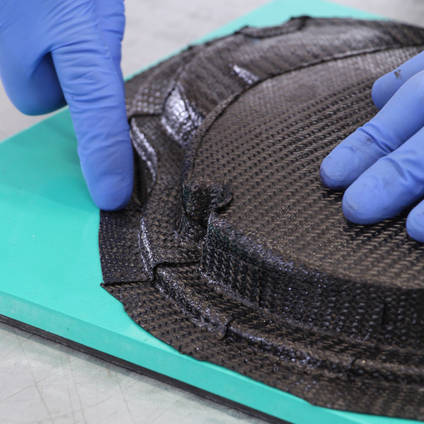

Surface ply for our XT135 out-of-autoclave prepreg carbon fiber tooling system. This is an uncured prepreg material and requires an oven or autoclave to cure it.

The XT135 tooling system can be cured in an oven under vacuum pressure only and used to produce high quality carbon fiber molds/tools suitable for high temperature use. A single layer of this special 250gsm (7.2oz/yd²) surface ply should be combined with two or more layers of the heavier backing ply should be combined with a single layer of surface ply.

This prepreg reinforcement is 1.25m/1250mm (49") wide and sold in a choice of prepacked roll lengths.

PRODUCT VERSIONS

Roll Length

79 more can built in 2-3 days

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

XPREG® XT135 is a specialist out of autoclave carbon fiber tooling prepreg. It is designed to produce dimensionally accurate carbon fibre composite molds using vacuum bag and oven cure only.

The tooling system is made up of XT135/S 250gsm (7.4oz/yd²) surface ply listed on this page and the XT135/B backing ply.

A lightweight composite mold suitable for modest production volumes can be produced using just one surface and two backing plies (subject to mold geometry) whilst the recommended laminate for a production mold is one surface and four backing plies. See technical datasheet for full details on suggested layups and layup considerations.

Typical Uses

XT135/S is an out of autoclave tooling prepreg surface layer, part of the XT135 tooling system developed specifically for out-of-autoclave cure and as such uses a special gelcoat-like filled resin surface. XT135 should be used for the production of composite tools for cure and use out-of-autoclave.

If tools are required for autoclave use then we would suggest our XT200 autoclave-cure tooling system which doesn't require filled resins and therefore offer slightly superior shrinkage and higher service temperatures.

The Sample Pack contains two 400x300mm (15.7x11.8") pieces of prepreg.

Further Information

Full details on the correct storage, handling and processing of XPREG XT135 can be found in safety and technical datasheets, and complete processing guide.

Storage & Handling

WARNING!! HIGHLY PERISHABLE

XPREG® XT135 surface ply uses a special almost dry scrim to maintain air paths to the surface and achieve a pinhole-free surface finish from an out-of-autoclave cure. This scrim is extremely sensitive to out-life and will start to ‘wet-out’ within 2-3 days at room temperature (20°C), closing the air paths to the surface and increasing the risk of pinholes on the mould’s surface. For this reason, we do not recommend ordering from the USA unless you are confident that there won't be any delivery delays and are aware of, and willing to accept the risks of international shipping of a highly temperature sensitive material.

Do NOT order this material during periods of high ambient temperatures (i.e. hot summer months).

Unless you plan to use the product immediately, it should be placed into frozen storage immediately on receipt.

Although orders to the USA are delivered 'duty paid', orders over $800 are still subject to a 'formal' customs entry procedure where US customs may contact you to confirm some details. We remind customers that when ordering perishable 'prepregs', Easy Composites cannot be held responsible for damage caused to the material by delays in customs clearance. By placing an order for prepreg materials, you accept these conditions of sale.

When not in use, XPREG® XT135 should be stored frozen at -18°C (0°F) in sealed plastic packaging.

XPREG® XT135 is a specialist out of autoclave carbon fiber tooling prepreg. It is designed to produce dimensionally accurate carbon fibre composite molds using vacuum bag and oven cure only.

The tooling system is made up of XT135/S 250gsm (7.4oz/yd²) surface ply listed on this page and the XT135/B backing ply.

A lightweight composite mold suitable for modest production volumes can be produced using just one surface and two backing plies (subject to mold geometry) whilst the recommended laminate for a production mold is one surface and four backing plies. See technical datasheet for full details on suggested layups and layup considerations.

Typical Uses

XT135/S is an out of autoclave tooling prepreg surface layer, part of the XT135 tooling system developed specifically for out-of-autoclave cure and as such uses a special gelcoat-like filled resin surface. XT135 should be used for the production of composite tools for cure and use out-of-autoclave.

If tools are required for autoclave use then we would suggest our XT200 autoclave-cure tooling system which doesn't require filled resins and therefore offer slightly superior shrinkage and higher service temperatures.

The Sample Pack contains two 400x300mm (15.7x11.8") pieces of prepreg.

Further Information

Full details on the correct storage, handling and processing of XPREG XT135 can be found in safety and technical datasheets, and complete processing guide.

Storage & Handling

WARNING!! HIGHLY PERISHABLE

XPREG® XT135 surface ply uses a special almost dry scrim to maintain air paths to the surface and achieve a pinhole-free surface finish from an out-of-autoclave cure. This scrim is extremely sensitive to out-life and will start to ‘wet-out’ within 2-3 days at room temperature (20°C), closing the air paths to the surface and increasing the risk of pinholes on the mould’s surface. For this reason, we do not recommend ordering from the USA unless you are confident that there won't be any delivery delays and are aware of, and willing to accept the risks of international shipping of a highly temperature sensitive material.

Do NOT order this material during periods of high ambient temperatures (i.e. hot summer months).

Unless you plan to use the product immediately, it should be placed into frozen storage immediately on receipt.

Although orders to the USA are delivered 'duty paid', orders over $800 are still subject to a 'formal' customs entry procedure where US customs may contact you to confirm some details. We remind customers that when ordering perishable 'prepregs', Easy Composites cannot be held responsible for damage caused to the material by delays in customs clearance. By placing an order for prepreg materials, you accept these conditions of sale.

When not in use, XPREG® XT135 should be stored frozen at -18°C (0°F) in sealed plastic packaging.

Specification

Fabric Specification

| Fibre Specifics | Toray T300 3k | |

|---|---|---|

| Colour | Black | |

| Type | Tooling Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric | |

| Filament Count | 3k | |

| Fibre Type | Carbon Fibre | |

| Brand | XPREG |

Weight and Dimensions

| Width | 1250 | mm |

|---|---|---|

| Consolidated Thickness | 0.7 | mm |

| Areal Weight | 250 | g/m² |

| Resin Weight | 67 | % |

Fibre Properties

| Min Cure Temp | 65 | °C |

|---|---|---|

| Max Cure Temp | 130 | °C |

| Max Service Temp | 135 | °C |

| Out-life (at 20°C) | 21 | Days |

| Freezer-life (at -18°C) | 12 | Months |

General Properties

| Gross Weight | 0.73 | kg |

|---|---|---|

| Brand | XPREG |

Unfortunately we do not stock any pre-pregs with a flexible resin. The only flexible resin we supply is our EF80 Flexible Epoxy Resin which is suitable for wet lay and vacuum bagged processes.

With the XPREG Tooling Pre-preg system, no additional gelcoat is needed. The Surface layer has sufficient resin in it to allow a good quality mould surface to be produced using just the Tooling system alone.

ASK YOUR OWN QUESTION

Customer Product Reviews for XT135/S 250g (7.2oz) 3k Tooling Prepreg Carbon 1250mm (49")

So far very impressed with this. Can't wait to pull a few parts from it...

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Login to submit a product reviewSUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Login to submit a product reviewShipping Information

WARNING!! HIGHLY PERISHABLE

This particular prepreg product is is highly perishable and for best results has a very short 'out-life' of just 2-3 days at room temperature. For this reason, we do not recommend ordering from the USA unless you are confident that there won't be any delivery delays and are aware of, and willing to accept the risks of international shipping of a highly temperature sensitive material.

Do NOT order this material during periods of high ambient temperatures (i.e. hot summer months).

Unless you plan to use the product immediately, it should be placed into frozen storage immeditely on receipt.

Because of their perishable nature, we only ship prepregs internationally on priority (air) services. As a result of this, it may not always be possible to order prepregs at the same time as some large or bulky items. If this is the case, the shipping calculator will warn you and suggest that you remove large items or place separate orders.

Customs Clearance

Although orders to the USA are delivered 'duty paid', orders over $800 are still subject to a 'formal' customs entry procedure where US customs may contact you to confirm some details. We remind customers that customs clearance is your responsibility and that when ordering perishable 'prepregs' it is important to respond quickly to any such request in order to avoid delay and potential damage to the material. Easy Composites cannot be held responsible for damage caused to prepregs during transport as a result of customs delays. By placing an order for prepreg materials, you accept these conditions of sale.

Package Size

When packaged, this product is over 1m in length. A small 'additional handling' charge will be included in the shipping cost.

Delivery Cost

To find the cost for delivery of this item to your address, add it to your cart then use the instant shipping calculator on the cart page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.