Need any help or advice?Contact Us

Specification

Weight and Dimensions

| Width | 1250 | mm |

|---|---|---|

| Consolidated Thickness | 0.1 | mm |

| Areal Weight | 163 | g/m² |

Fibre Properties

| Out-life (at 20°C) | 30 | Days |

|---|

Product Data

| Colour | White | |

|---|---|---|

| Type | Adhesive Film | |

| Format | Flat Film | |

| Brand | XPREG |

Mechanical Properties

| Resin Matrix | Epoxy | |

|---|---|---|

| Min Cure Temp | 80 | °C |

| Max Cure Temp | 120 | °C |

| Max Service Temp | 120 | °C |

General Properties

| Gross Weight | 0.52 | kg |

|---|---|---|

| Brand | XPREG |

Shipping Information

Non Hazardous

This product is not classed as dangerous goods for transport and can be shipped to all US addresses without restriction.

Prepregs are Perishable!

Prepreg materials are stored in our freezers at -20°C (-4°F) and are shipped from our warehouse still frozen. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Because of their perishable nature, we only ship prepregs internationally on priority (air) services. As a result of this, it may not always be possible to order prepregs at the same time as some large or bulky items. If this is the case, the shipping calculator will warn you and suggest that you remove large items or place separate orders.

Customs Clearance

Although orders to the USA are delivered 'duty paid', orders over $800 are still subject to a 'formal' customs entry procedure where US customs may contact you to confirm some details. We remind customers that customs clearance is your responsibility and that when ordering perishable 'prepregs' it is important to respond quickly to any such request in order to avoid delay and potential damage to the material. Easy Composites cannot be held responsible for damage caused to prepregs during transport as a result of customs delays. By placing an order for prepreg materials, you accept these conditions of sale.

Package Size

When packaged, this product is over 1m in length. A small 'additional handling' charge will be included in the shipping cost.

Delivery Cost

To find the cost for delivery of this item to your address, add it to your cart then use the instant shipping calculator on the cart page.

XA120 150g (4.4oz) Prepreg Adhesive Film 1250mm (49”)

- XPREG

- XA120-GPL-150(1250)-1

- No reviews

High performance 150gsm (4.4oz/yd²) oven-cure prepreg adhesive film used for bonding honeycomb cores, such as aluminum and Nomex, and structural foams, such as Rohacell into composite laminate structures.

This adhesive film is 1.25m (49") wide and available to buy in choice of pre-packed roll lengths.

PRODUCT VERSIONS

Roll Length

122 more can built in 2-3 days

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

150gsm (4.4oz/yd²) XPREG® XA120 is a structural epoxy adhesive film used to provide a high strength bond between composite laminate and core materials such as aluminum honeycomb, Nomex® or foam core (such as Rohacell®). This film adhesive can also be used to provide additional resin around bonding fasteners and inserts or underneath peel-ply when using peel-ply to provide a secondary bonding surface.

XA120's advanced, toughened epoxy formulation results in outstanding bond and peel-strength at the very forefront of adhesive film performance.

This prepreg resin film is suitable for autoclave, oven or heated platen press cure. XA120 cannot be cured at room temperature.

Advantages

- Industry leading bond and peel-strength

- Service temperature up to 120°C (248°F) (subject to post-cure)

- Easy handling (4 week out-life)

- Minimal shrinkage, very low CTE

- Fully compatible with XPREG® XC110 and XC130 prepregs

Further Information

Cure Cycle

The recommended cure cycle for XA120 is 8hrs at 90°C (194°F) (ramp rate 2°C (1°F) /min) which will result in a Tg of 100°C (212°F). Where the maximum Tg is required, a post cure of 120°C (248°F) for 1hr should be followed (ramp rate 0.3°C (0.5°F) /min).

See datasheet for full details including alternative cure cycles from 80°C (176°F).

Compatibility with XPREG® Prepregs

XA120 is fully compatible with XPREG° XC110 (out-of-autoclave) and XC130 (autoclave) cure prepregs and can be co-cured with these prepreg systems or used in a '2-shot' process to provide secondary bonding onto laminates made using these systems (peel-ply finish or surface preparation would be required).

150gsm (4.4oz/yd²) XPREG® XA120 is a structural epoxy adhesive film used to provide a high strength bond between composite laminate and core materials such as aluminum honeycomb, Nomex® or foam core (such as Rohacell®). This film adhesive can also be used to provide additional resin around bonding fasteners and inserts or underneath peel-ply when using peel-ply to provide a secondary bonding surface.

XA120's advanced, toughened epoxy formulation results in outstanding bond and peel-strength at the very forefront of adhesive film performance.

This prepreg resin film is suitable for autoclave, oven or heated platen press cure. XA120 cannot be cured at room temperature.

Advantages

- Industry leading bond and peel-strength

- Service temperature up to 120°C (248°F) (subject to post-cure)

- Easy handling (4 week out-life)

- Minimal shrinkage, very low CTE

- Fully compatible with XPREG® XC110 and XC130 prepregs

Further Information

Cure Cycle

The recommended cure cycle for XA120 is 8hrs at 90°C (194°F) (ramp rate 2°C (1°F) /min) which will result in a Tg of 100°C (212°F). Where the maximum Tg is required, a post cure of 120°C (248°F) for 1hr should be followed (ramp rate 0.3°C (0.5°F) /min).

See datasheet for full details including alternative cure cycles from 80°C (176°F).

Compatibility with XPREG® Prepregs

XA120 is fully compatible with XPREG° XC110 (out-of-autoclave) and XC130 (autoclave) cure prepregs and can be co-cured with these prepreg systems or used in a '2-shot' process to provide secondary bonding onto laminates made using these systems (peel-ply finish or surface preparation would be required).

Specification

Weight and Dimensions

| Width | 1250 | mm |

|---|---|---|

| Consolidated Thickness | 0.1 | mm |

| Areal Weight | 163 | g/m² |

Fibre Properties

| Out-life (at 20°C) | 30 | Days |

|---|

Product Data

| Colour | White | |

|---|---|---|

| Type | Adhesive Film | |

| Format | Flat Film | |

| Brand | XPREG |

Mechanical Properties

| Resin Matrix | Epoxy | |

|---|---|---|

| Min Cure Temp | 80 | °C |

| Max Cure Temp | 120 | °C |

| Max Service Temp | 120 | °C |

General Properties

| Gross Weight | 0.52 | kg |

|---|---|---|

| Brand | XPREG |

Unfortunately we do not stock any pre-pregs with a flexible resin. The only flexible resin we supply is our EF80 Flexible Epoxy Resin which is suitable for wet lay and vacuum bagged processes.

No, XA120 Prepreg Adhesive film is designed to be used as an adhesive, particularly for bonding core materials to laminates as part of single or multi stage cure processes. It is not designed to be used as a 'resin film' or 'surface film' and in testing did not prove suitable for this application.

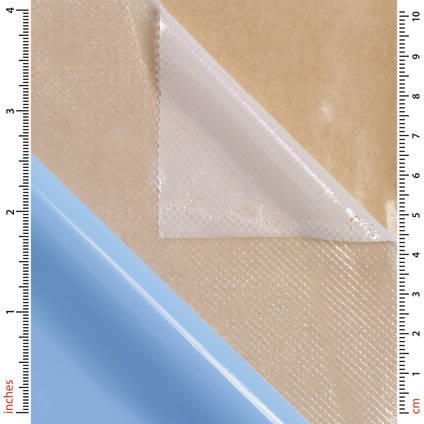

Unfortunately not. The XA120 contains a glass scrim that means you would not get a great cosmetic finish to a part. It is designed as an adhesive film only.

The film is nominally around 0.2mm thick in its uncured state. However, post curing, the thickness will reduce and vary depending on the use and curing process.

ASK YOUR OWN QUESTION

Customer Product Reviews for XA120 150g (4.4oz) Prepreg Adhesive Film 1250mm (49”)

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Login to submit a product reviewSUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Login to submit a product reviewShipping Information

Non Hazardous

This product is not classed as dangerous goods for transport and can be shipped to all US addresses without restriction.

Prepregs are Perishable!

Prepreg materials are stored in our freezers at -20°C (-4°F) and are shipped from our warehouse still frozen. This prepreg has an 'out-life' of at least 30 days at room temperature and so typical delivery times will still leave plenty of 'out-life' remaining.

During summer months or periods of hot weather, it is recommended to order prepregs at the start of the week (Monday or Tuesday) to avoid adding extra shipping days over the weekend.

Unless you plan to use the product immediately, it should be placed into frozen storage as soon as possible on receipt.

Because of their perishable nature, we only ship prepregs internationally on priority (air) services. As a result of this, it may not always be possible to order prepregs at the same time as some large or bulky items. If this is the case, the shipping calculator will warn you and suggest that you remove large items or place separate orders.

Customs Clearance

Although orders to the USA are delivered 'duty paid', orders over $800 are still subject to a 'formal' customs entry procedure where US customs may contact you to confirm some details. We remind customers that customs clearance is your responsibility and that when ordering perishable 'prepregs' it is important to respond quickly to any such request in order to avoid delay and potential damage to the material. Easy Composites cannot be held responsible for damage caused to prepregs during transport as a result of customs delays. By placing an order for prepreg materials, you accept these conditions of sale.

Package Size

When packaged, this product is over 1m in length. A small 'additional handling' charge will be included in the shipping cost.

Delivery Cost

To find the cost for delivery of this item to your address, add it to your cart then use the instant shipping calculator on the cart page.

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

RELATED PRODUCTS

CUSTOMERS ALSO PURCHASED

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.