Need any help or advice?Contact Us

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

PATTERN MAKING MATERIALS

CUSTOMER GALLERY

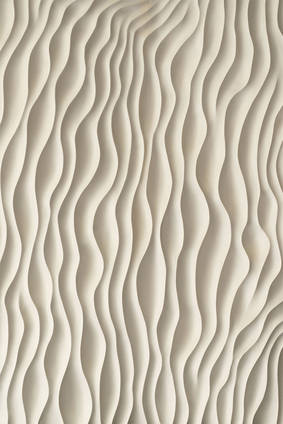

Kelp Forest Inspired Hand Carving

This hand-carved pattern was inspired by time spent free-diving through kelp forests in Cornwall, evoking the peaceful, silent world beneath the waves. The flowing forms capture the rhythm of water, the gentle sway of marine life, and the sense of stillness and immersion found beneath the surface.

Jesmonite is a composite material made of two main components: a modified gypsum-based material powder and a water-based acrylic resin. It has a lovely feel to it and it can be cast to replicate fine textures and details. Theo was developing a wall mounted drinks cabinet and wanted this to have a carved, textured front. As a way to experiment with Jesmonite as a material, Theo devised to produce a piece of wall art, that could then be batch produced to offset the time spent in carving the pattern.

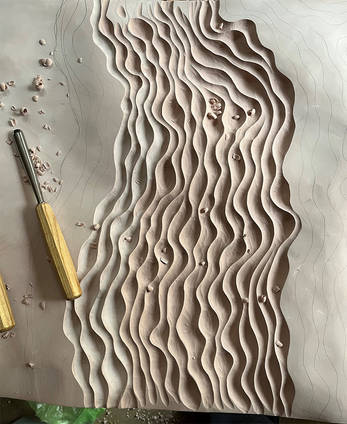

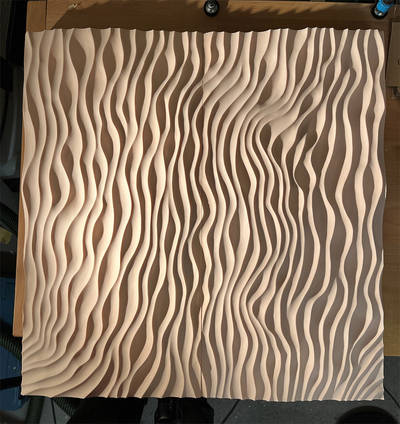

The process started with some of Easy Composites' PU600 Polyurethane Model Board. He then created an undulating surface on one side of this with an angle grinder and then sanded this smooth. This was the substrate on which he could then draw his pattern and carve into. Being a uniform material, the PU600 Model Board is easy to carve, without the challenges of grain direction that you have to face with wood. Using a number of rounded gouges, Theo carved out the pattern that he wanted, before sanding everything down to get a good smooth surface for casting. He finished the board with some S120 Board sealer and a release wax.

The next step was to create a mould from which he could make the castings. This was done with a CS25 Condensation Cure silicone. It released easily to create a perfect mould into which Theo could cast the Jesmonite. Carving the pattern took a long time but the benefit of this technique means that once he had produced the mould, he could then take repeat castings from this in a short space of time, thereby recouping the initial outlay of time and effort.

The Jesmonite casting involved pouring a number of layers of Jesmonite into the mould, with glass fibre matting and chopped glass fibres to reinforce the piece and provide structural integrity. Theo likes working with light and shadow and thus added some white pigment to the Jesmonite to create a clean finish that emphasised the shadows of the carved pattern.

Finally, with the casting complete, Theo flattened the back of the piece on a wide-belt sander and made a simple wooden frame in which to mount the finished piece.

ABOUT THEO SILKSTONE

Theo Silkstone is a bespoke furniture maker based near Oxford. He had originally studied Materials Science at Oxford and has carried forward this interest and experimentation with materials in his furniture design today. The interplay of light, texture and tactility are central to his design work and he has recently started a series of work casting Jesmonite, which offers a perfect medium for conveying these key themes.

CONTACT INFORMATION

| Website | www.theosilkstone.com |

|---|

| @theo_silkstone |

USED IN THIS PROJECT

Although not necessarily an exhaustive list, the following tools and materials, supplied by Easy Composites, were used in this project.

The quantity shown below is the approximate amount used in the project rounded up to the nearest available kit size or quantity.

PATTERN MAKING MATERIALS

ABOUT THEO SILKSTONE

Theo Silkstone is a bespoke furniture maker based near Oxford. He had originally studied Materials Science at Oxford and has carried forward this interest and experimentation with materials in his furniture design today. The interplay of light, texture and tactility are central to his design work and he has recently started a series of work casting Jesmonite, which offers a perfect medium for conveying these key themes.

CONTACT INFORMATION

| Website | www.theosilkstone.com |

|---|

| @theo_silkstone |

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.