Need any help or advice?Contact Us

Downloads (1)

| Technical Datasheet (TDS) |

Specification

Weight and Dimensions

| Length | 285 | mm |

|---|---|---|

| Width | 140 | mm |

Product Data

| Colour | Black | |

|---|---|---|

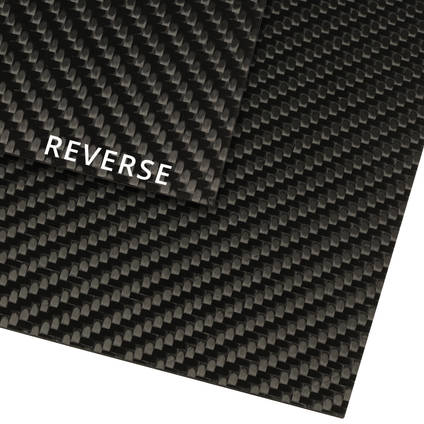

| Appearance | 2x2 Twill (Glossy) | |

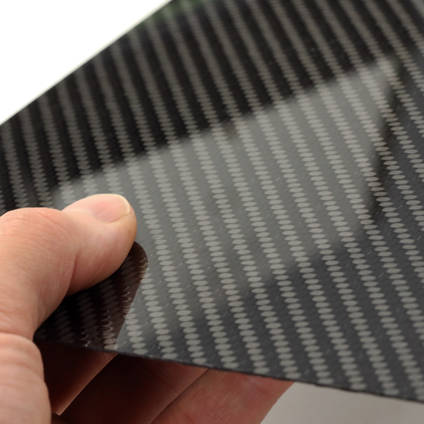

| Thickness | 0.25 | mm |

| Type | Double Sided | |

| Fibre Orientation | 0, 90 |

Cured Mechanical Properties

| Tensile Strength at 0/90° | 641 | MPa |

|---|---|---|

| Tensile Modulus at 0/90° | 50100 | MPa |

Mechanical Properties

| Resin Matrix | Epoxy | |

|---|---|---|

| Tg Onset (DMA) | 80 | °C |

General Properties

| Gross Weight | 0.015 | kg |

|---|

Shipping Information

Non Hazardous

This product is not classed as dangerous goods for transport and can be shipped to all US addresses without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the cost for delivery of this item to your address, add it to your cart then use the instant shipping calculator on the cart page.

Double-Sided High Strength Carbon Fiber Sheet

- CFS-PP-0.25-0040

- No reviews

Manufactured by Easy Composites in the UK. Double-sided carbon fiber sheets manufactured from 100% high-strength prepreg carbon fiber, pressed at high temperature and pressure between polished plattens to produce the highest quality carbon fiber sheet available. Smooth, flat, gloss finish on both sides suitable for cosmetic or structural applications including motorsport, aerospace, engineering, drones/UAVs, modelling and more.

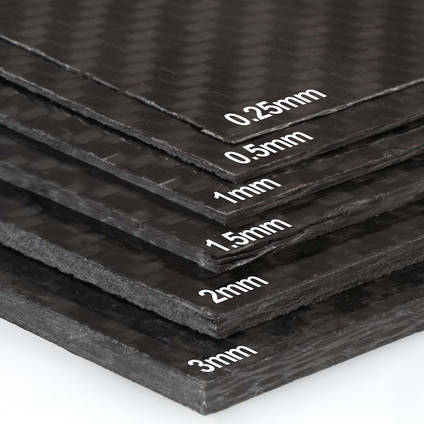

Available in 0.25mm, 0.5mm, 1mm, 1.5mm, 2mm, 3mm (0.01, 0.02, 0.04, 0.06, 0.08, 0.12") thicknesses in a variety of sheet sizes up to 580 x 580mm (approx 23 x 23").

PRODUCT VERSIONS

Sheet Size

Thickness

Trade discounts

| 0-4 | 5-9 | 10+ |

|---|---|---|

| $24.65 | $23.00 | $21.45 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

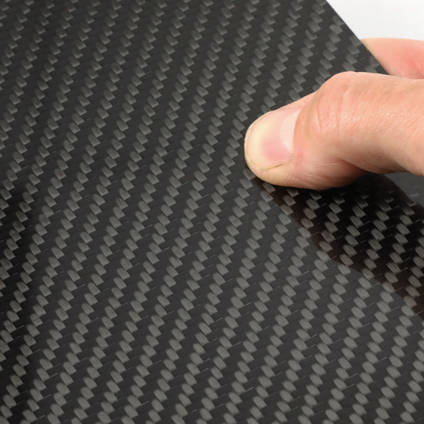

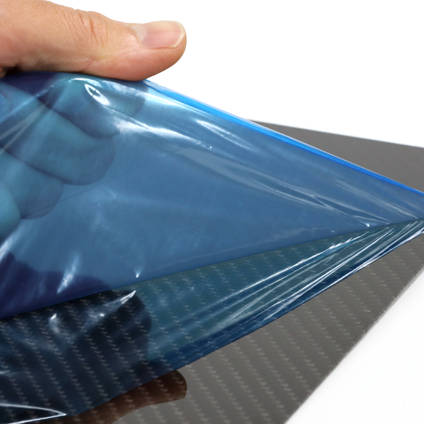

Designed to meet the most exacting standards of any carbon fiber sheet, our Double Sided High Strength Carbon Fiber Sheet is manufactured from 100% carbon fiber reinforcement and pressed at high temperature and pressure to create a high performance double sided carbon fiber sheet with a smooth, high-gloss finish on both sides.

Typical Uses:

- General Engineering

- Robotics

- Aerospace

- Motorsport

- X-Ray/Metrology Equipment

- R/C Models

Advantages

- Good flatness (minimal taper or warp)

- High gloss finish on both sides

- Pin-hole free surface finish

How to Buy

Our Double Sided High Strength Carbon Fiber Sheet is available to buy in thicknesses of 0.25mm (0.01"), 0.5mm (0.02"), 1mm (0.04"), 1.5mm (0.06") 2mm (0.08") and 3mm (0.12"). Choose your required thickness at the top of the page.

The sheet is also available in sheet sizes 285 x 140mm (12.2 x 5.51"), 285 x 285mm (11.2 x 11.2"), 580mm x 285mm (22.8 x 11.2") and 580mm x 580mm (22.8 x 22.8") which should also be selected at the top of the page.

Further Information

Technical Data

Manufacturing Process

These sheets are made in-house in our specially designed platen press.

By manufacturing in-house we can supply the highest quality prepreg carbon fiber sheet available at the best possible price; a combination that has won us ongoing contracts supplying some of the biggest names in technology, engineering and motor-sport.

Laminate Composition

The matrix used is a high performance epoxy resin which offers excellent mechanicals, clarity and improved UV stability. The high temperature cure maximises the mechanical strength properties and results in a Tg (glass transition) of 80°C.

Our Double Sided High Strength Carbon Fiber Sheet is manufactured from multiple layers of our XPREG XC130 Prepreg Carbon 3K, 210g, 2/2 Twill and our XPREG XC130 Prepreg Carbon Fiber 12K, 450g, 2/2 Twill in the following lay up schedules:

| 0.25mm | 0.5mm | 1mm | 1.5mm | 2mm | 3mm |

|---|---|---|---|---|---|

| XC130 210g | XC130 210g XC130 210g |

XC130 210g XC130 450g XC130 210g |

XC130 210g XC130 450g XC130 210g XC130 450g XC130 210g |

XC130 210g XC130 450g XC130 210g XC130 450g XC130 450g XC130 210g |

XC130 210g XC130 450g XC130 450g XC130 210g XC130 450g XC130 450g XC130 450g XC130 210g |

Thickness Tolerance and Sheet Weight

Thickness tolerance and weight for our Double A-Side High Strength Carbon Fiber Sheet varies with thickness, as follows:

| Thickness | Actual Thickness and Tolerance | Weight kg/m² |

| 0.25mm | 0.22 +/-0.1mm | 0.35 |

| 0.5mm | 0.44 +/-0.1mm | 0.74 |

| 1mm | 0.86 +/-0.15mm | 1.42 |

| 1.5mm | 1.61 +/-0.20mm | 2.41 |

| 2mm | 1.78 +/-0.20mm | 2.98 |

| 3mm | 2.82 +/-0.25mm | 4.22 |

How to Cut and Shape

This carbon fiber sheet can easily be cut and finished to a high standard using simple workshop tools. Cutting and finishing carbon fiber can also be perfectly safe if you follow some basic safety precautions.

For a comprehensive guide to both safety advice and cutting and finishing techniques watch our Easy Composites video guide to cutting and shaping carbon fiber sheet and carbon fiber parts.

Manufacturing Contracts

If you are an established manufacturing business looking for a reliable supplier of engineering quality carbon fiber sheet please call us to discuss your requirements or arrange to see some samples.

Our production facilities mean we can manufacture prepreg carbon fiber or hybrid composite sheet to just about any specification, often with little or no setup cost:

- Custom thickness

- Custom fiber orientation

- Competitive volume pricing

Regrettably, we are unable to offer custom sheet fabrication for small runs (less than 10sqm). We do not offer a cutting/trimming service.

Trade discounts

| 0-4 | 5-9 | 10+ |

|---|---|---|

| $24.65 | $23.00 | $21.45 |

We won’t be beaten on price!

If you believe you’re buying an equivalent product cheaper elsewhere, contact us to discuss your requirements.

Designed to meet the most exacting standards of any carbon fiber sheet, our Double Sided High Strength Carbon Fiber Sheet is manufactured from 100% carbon fiber reinforcement and pressed at high temperature and pressure to create a high performance double sided carbon fiber sheet with a smooth, high-gloss finish on both sides.

Typical Uses:

- General Engineering

- Robotics

- Aerospace

- Motorsport

- X-Ray/Metrology Equipment

- R/C Models

Advantages

- Good flatness (minimal taper or warp)

- High gloss finish on both sides

- Pin-hole free surface finish

How to Buy

Our Double Sided High Strength Carbon Fiber Sheet is available to buy in thicknesses of 0.25mm (0.01"), 0.5mm (0.02"), 1mm (0.04"), 1.5mm (0.06") 2mm (0.08") and 3mm (0.12"). Choose your required thickness at the top of the page.

The sheet is also available in sheet sizes 285 x 140mm (12.2 x 5.51"), 285 x 285mm (11.2 x 11.2"), 580mm x 285mm (22.8 x 11.2") and 580mm x 580mm (22.8 x 22.8") which should also be selected at the top of the page.

Further Information

Technical Data

Manufacturing Process

These sheets are made in-house in our specially designed platen press.

By manufacturing in-house we can supply the highest quality prepreg carbon fiber sheet available at the best possible price; a combination that has won us ongoing contracts supplying some of the biggest names in technology, engineering and motor-sport.

Laminate Composition

The matrix used is a high performance epoxy resin which offers excellent mechanicals, clarity and improved UV stability. The high temperature cure maximises the mechanical strength properties and results in a Tg (glass transition) of 80°C.

Our Double Sided High Strength Carbon Fiber Sheet is manufactured from multiple layers of our XPREG XC130 Prepreg Carbon 3K, 210g, 2/2 Twill and our XPREG XC130 Prepreg Carbon Fiber 12K, 450g, 2/2 Twill in the following lay up schedules:

| 0.25mm | 0.5mm | 1mm | 1.5mm | 2mm | 3mm |

|---|---|---|---|---|---|

| XC130 210g | XC130 210g XC130 210g |

XC130 210g XC130 450g XC130 210g |

XC130 210g XC130 450g XC130 210g XC130 450g XC130 210g |

XC130 210g XC130 450g XC130 210g XC130 450g XC130 450g XC130 210g |

XC130 210g XC130 450g XC130 450g XC130 210g XC130 450g XC130 450g XC130 450g XC130 210g |

Thickness Tolerance and Sheet Weight

Thickness tolerance and weight for our Double A-Side High Strength Carbon Fiber Sheet varies with thickness, as follows:

| Thickness | Actual Thickness and Tolerance | Weight kg/m² |

| 0.25mm | 0.22 +/-0.1mm | 0.35 |

| 0.5mm | 0.44 +/-0.1mm | 0.74 |

| 1mm | 0.86 +/-0.15mm | 1.42 |

| 1.5mm | 1.61 +/-0.20mm | 2.41 |

| 2mm | 1.78 +/-0.20mm | 2.98 |

| 3mm | 2.82 +/-0.25mm | 4.22 |

How to Cut and Shape

This carbon fiber sheet can easily be cut and finished to a high standard using simple workshop tools. Cutting and finishing carbon fiber can also be perfectly safe if you follow some basic safety precautions.

For a comprehensive guide to both safety advice and cutting and finishing techniques watch our Easy Composites video guide to cutting and shaping carbon fiber sheet and carbon fiber parts.

Manufacturing Contracts

If you are an established manufacturing business looking for a reliable supplier of engineering quality carbon fiber sheet please call us to discuss your requirements or arrange to see some samples.

Our production facilities mean we can manufacture prepreg carbon fiber or hybrid composite sheet to just about any specification, often with little or no setup cost:

- Custom thickness

- Custom fiber orientation

- Competitive volume pricing

Regrettably, we are unable to offer custom sheet fabrication for small runs (less than 10sqm). We do not offer a cutting/trimming service.

Downloads (1)

| Technical Datasheet (TDS) |

Specification

Weight and Dimensions

| Length | 285 | mm |

|---|---|---|

| Width | 140 | mm |

Product Data

| Colour | Black | |

|---|---|---|

| Appearance | 2x2 Twill (Glossy) | |

| Thickness | 0.25 | mm |

| Type | Double Sided | |

| Fibre Orientation | 0, 90 |

Cured Mechanical Properties

| Tensile Strength at 0/90° | 641 | MPa |

|---|---|---|

| Tensile Modulus at 0/90° | 50100 | MPa |

Mechanical Properties

| Resin Matrix | Epoxy | |

|---|---|---|

| Tg Onset (DMA) | 80 | °C |

General Properties

| Gross Weight | 0.015 | kg |

|---|

Whether or not cut edges would benefit from sealing really comes down to the application and environment where the sheet will be used, specifically, we're really talking about prolonged or permanent exposure to liquids like water, chemicals, oil etc. In an application where the cut edge of the sheet is going to be regularly or permanently exposed to liquids then it would be beneficial to seal the edge to prevent water ingress which, over enough time, can travel down the fibres and cause delamination.

Based on the above, if edge sealing is deemed advantageous then it's best done using some epoxy resin which should be mixed (according to its accompanying instructions) and either be brushed or smeared on the cut edge, or the cut edge dipped in it. Although it's by no means critical, a particularly suitable resin would be our XCR Epoxy Coating Resin.

It's not possible to give an exact weight because it would depend on many things (how the sheet is supported, what the span in, how the weight it loaded, whether the sheet is a 'free span' (i.e. not bonded/fixed) or bonded or fixed (so you get a 'drum skin' effect). That said, you could be confident that a sheet slid over a hole such that the sheet is supported on all sides would support the weight of an average person quite easily.

The 0.25mm sheet is made from a single layer of pre-preg carbon fibre. The vast majority of the sheet is a uniform carbon fibre finish, however there is occasionally a small gap in the weave pattern that will allow light to pass through the sheet.

Due to the nature of the foam core and bond strength over such a large area, using an epoxy resin as an adhesive would work fine for most applications. On a practical side, with the EL2, you can have a good working time to evenly cover the sheet and assemble the panel compared to the very short working time of the VM100 Adhesive. The bonding surfaces of the carbon sheet will need to be sanded to give a rough key to help with adhesion.

The 0.25mm sheet is a single layer of carbon. Although the resin does flow during the cure and is likely to ensure any slight gaps between the fibres are filled with resin, it is impossible to say it would be totally pinhole free and air tight. So there is the possibility of air being able to get through. The thicker the sheet, the more layers and the less chance a pinhole could form an air path all the way through.

No, the sheets are made up of fibres orientated at the 0 and 90 degree orientations so are not quasi-isoptropic.

These sheets have a maximum service temperature of 100°C.

The weave pattern of the sheets is a 2/2 twill weave.

I guess you're asking if it can be heated and re-formed (like softening and bending a thermoplastic). If so then no; this is a cured, rigid sheet, its shape cannot be changed other than cutting it. The only way you can shape a prepreg is to buy our Easy Composite's uncured prepreg carbon fibre. You would then need to vacuum bag the prepreg in a mould and cure it in an oven. Because there's quite a few materials and bits of equipment involved in this process and you are interested in curing your own prepregs then we have, under our Easy Composites brand, put together a Prepreg Carbon Fibre Starter Kit which includes everything you would need.

All the thickness of sheets we sell will accept being bent in small angles over a radius without a problem. The thinner sheets can be bent over a radius by a considerable amount without failure. The sheet will try to return to its original flat shape so for a curved panel, it would need to be bonded or fixed in plate to hold that shape.

Due to the nature of the composite structure, any such bending needs to be over a radius. Trying to create a sharp bend or fold will cause the sheets to fracture and fail around the fold edge.

In double-sided carbon fibre sheet we don't have sheets larger than 580x580mm - this is because of the way the double-sided sheets are manufactured. However, we do now have our new single sided high strength sheets which are also 100% carbon fibre and have the same mechanical properties as the double sided sheet but is available in sheet sizes up to 2m x 1m.

ASK YOUR OWN QUESTION

Customer Product Reviews for Double-Sided High Strength Carbon Fiber Sheet

SUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Login to submit a product reviewSUBMIT YOUR OWN PRODUCT REVIEW

We publish all reviews for verified purchases. Submit your own review and help other customers with their choices.Login to submit a product reviewShipping Information

Non Hazardous

This product is not classed as dangerous goods for transport and can be shipped to all US addresses without restriction.

Package Size

There are no package size restrictions or surcharges for this product.

Delivery Cost

To find the cost for delivery of this item to your address, add it to your cart then use the instant shipping calculator on the cart page.

100% SECURE

PAYMENT METHODS

Easy Composites Ltd, registered in England 7486797. All content copyright (C) Easy Composites Ltd, 2025. All rights reserved.